Brief introduction

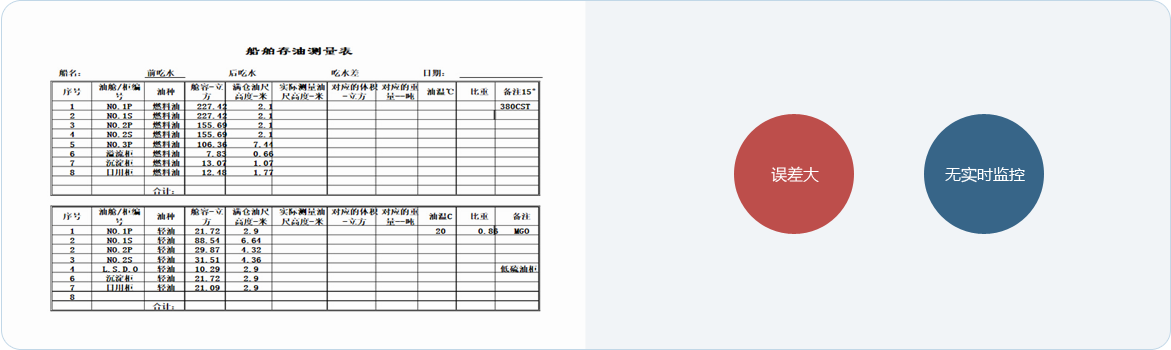

All along, the ship's fuel management is inventory management, rely on

the amount of oil products tanks for manual measurements. Measurement

error, time-consuming and can not do real-time monitoring. So now most

of the ship's fuel monitoring are only extensive management.

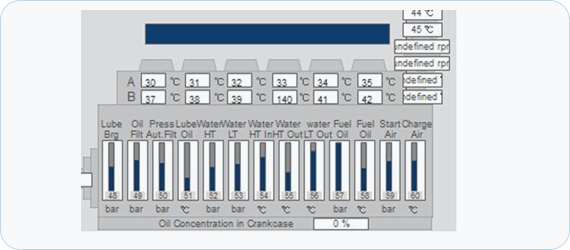

The bunker system in order to achieve data parameter monitoring function, providing an intuitive digital form contrast.

Historical data can be combined with the establishment of early warning and alarm.

background

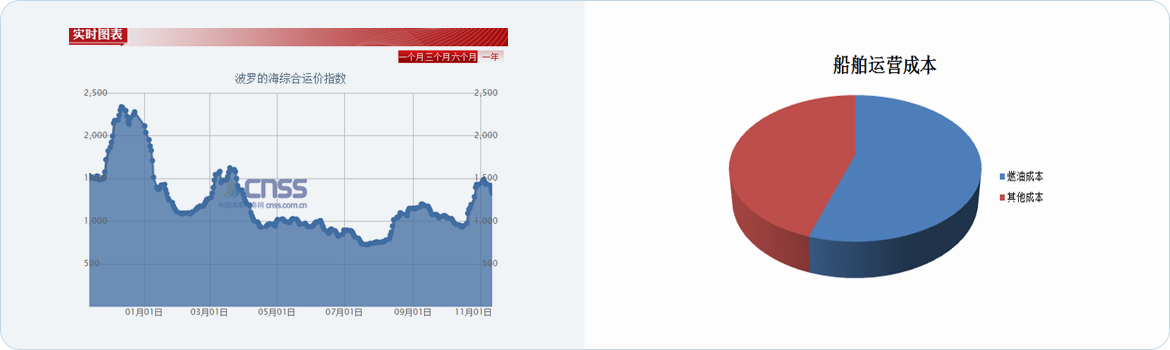

In the current shipping market downturn, lower ship operating costs is

the most important shipping companies to ship management. And reduce

fuel consumption, but also the most direct vessel operating costs and

effective means to reduce.

All along, the ship's fuel management is inventory management, rely on the amount of oil products tanks for manual measurements. Measurement error, time-consuming and can not do real-time monitoring. So now most of the ship's fuel monitoring are only extensive management.

Fuel monitoring system change

management ideas, from inventory management into consumption management;

to monitor host and auxiliary machinery, boilers and other equipment to

monitor real-time fuel consumption from oil tanks store. Combined with

the actual ship basic information, it offers a variety of alarm

conditions and alarm means so that the accuracy of the fuel monitoring

is greatly increased.

Features

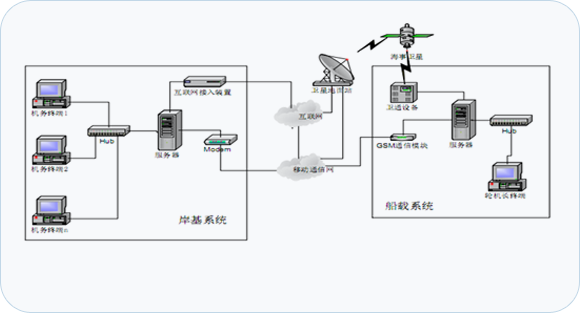

System

is divided into data acquisition, data transmission, shore-side monitor

three parts. Data collection utilizing existing meter ship, power meter

and other equipment, with ship-based data, automatic capture, transmit,

calculations, alarms, data provide direct evidence for ship management.

It

provides comprehensive alarm settings and timely data transmission,

will be able to detect problems at the beginning of ship fuel

abnormalities.

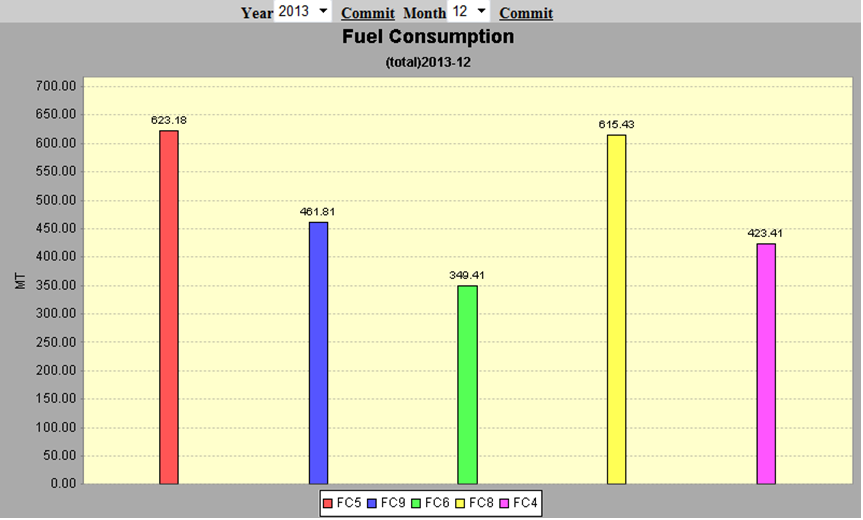

Customizable data analysis, generate a

variety of reports based on an intuitive graphical monitoring results

for reference.

Data transmission

Depending on the ship hardware facilities and customer requirements, it can automatically transmit data or manual data transfer. For the installation of the AMOS, RYDEX, Skyfile ship, vessel or offshore support 3G online for a long time, it can automatically transmit data, daily transfer amount does not exceed 5K bytes (once every 24 hours to monitor the calculation). And the company can automatically receive import terminal. For ships not installed M station, F stations, satellite communication equipment, available mail, U disk and other forms of manual transmission.

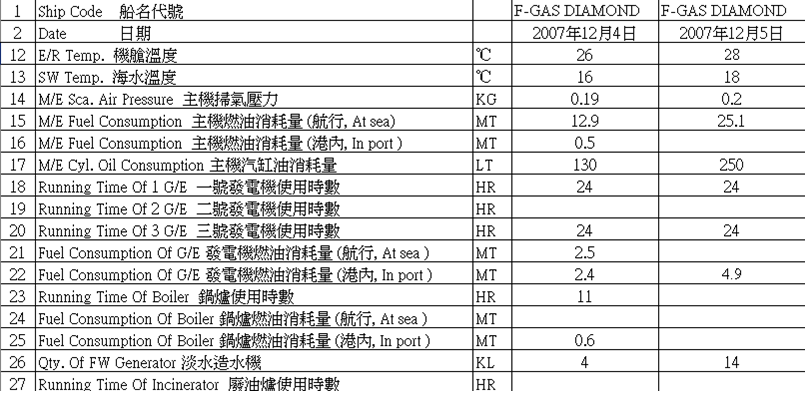

Collecting data

According to ship hardware facilities and different customer

requirements can be collected automatically or manually fill. For

automatic acquisition, depending on the ship facilities that may need to

install control boxes, sensors, converters or signal repeaters.

Monitoring alarm

Currently, the system offers alarm points are as follows:

● Host (auxiliary unit, boiler) to calculate fuel consumption (cubic meters / ton) and reporting consumption (cubic meters / tonne) difference or ratio;

● slip loss rate calculated and reported value difference or ratio;

● Host reporting on fuel consumption with the theoretical lower limit difference or ratio;

● abnormal fuel alarm;

● above and modify the alarm value can be specified by the company;

● alarm mode according to user needs, through the program, e-mail, SMS, etc. alarm.

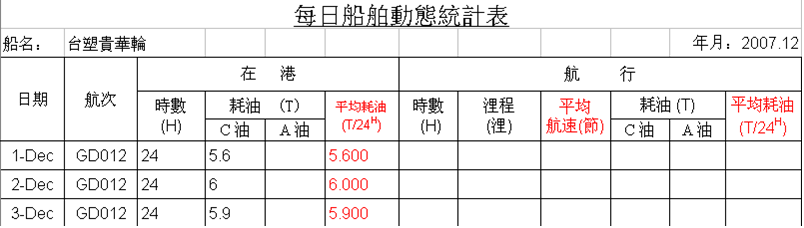

Data entry and statistical master / chief engineer fill in something like daily reports

Can automatically generate day / month dynamic tables by the above statements, make statistics more efficient, more accurate

Compare the same type of ship fuel

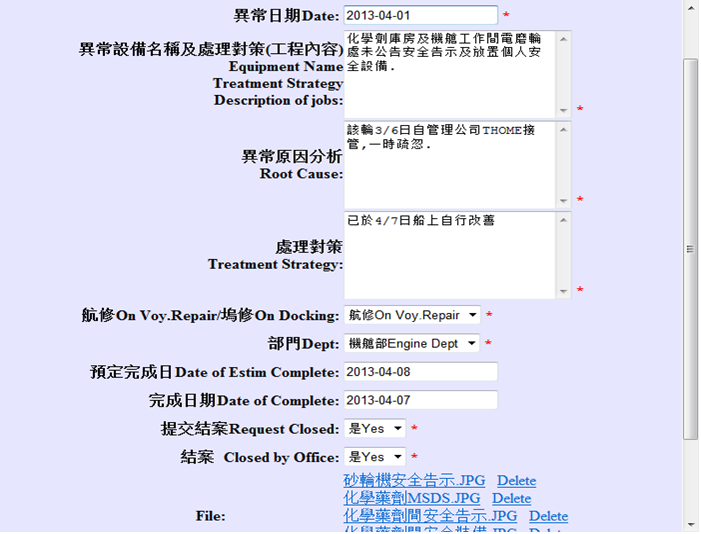

Exception Management Process